DQ Application PDF: A Comprehensive Guide

DQ application PDFs encompass diverse areas – dental exams, advocate insight days, job opportunities, and technical data sheets like DrägerSensors DQ․

Understanding the DQ Application Process

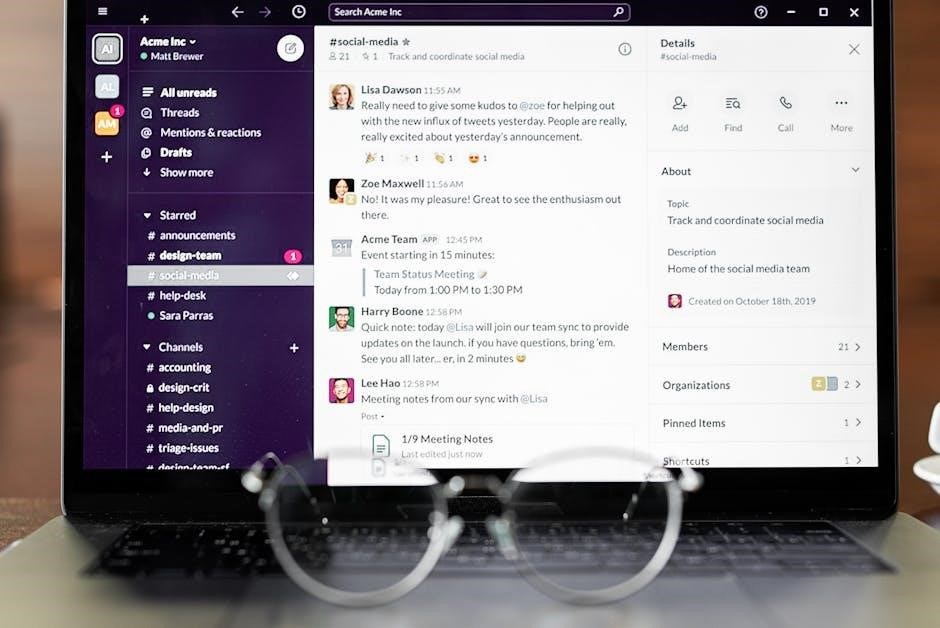

Navigating the DQ application process requires recognizing its multifaceted nature․ Depending on the context – be it a Dental DQ application for the 2023 exam, an application for DQ Advocates Insight Days, a Dairy Queen job application, or a technical request for DrägerSensors DQ data – the procedure differs significantly․

Generally, the process begins with accessing the relevant PDF form․ These PDFs, available online, detail specific requirements and instructions․ Dairy Queen encourages online applications for corporate roles, while store positions often involve a direct request for a physical application․ For specialized applications like those from CEPAL or Binderholz, accessing the correct PDF is crucial for utilizing their tools or construction guides․

Successful completion hinges on carefully reviewing instructions, gathering required documentation, and accurately filling out the form․ Understanding the specific demands of each DQ application type is paramount for a smooth and efficient experience․

What is a DQ Application?

A “DQ Application” is a broad term encompassing various request formats utilized across different sectors associated with the DQ brand and beyond․ It isn’t a single, unified form, but rather a category of applications tailored to specific needs; These range from seeking employment at Dairy Queen, requiring a standard job application, to accessing specialized technical documentation like DrägerSensors DQ data sheets․

In the dental field, a DQ application refers to materials – often in PDF format – used for exam preparation, potentially including MCQs․ Similarly, DQ Advocates Insight Days necessitate a specific application form to assess candidate suitability․ Even wood construction solutions from Binderholz utilize application guides, effectively functioning as DQ applications for their products․

Essentially, a DQ application represents a formal request for something – a job, information, access, or consideration – within the DQ ecosystem or related industries․

Types of DQ Applications Available

The spectrum of DQ Applications is remarkably diverse, reflecting the breadth of areas where “DQ” appears․ Dairy Queen job seekers encounter standard employment applications, available online or in-store, seeking basic candidate information․ For professionals, DQ Advocates Insight Days require a dedicated application form, assessing skills and interest․

Technical applications include DrägerSensors DQ data sheets – essential for proper usage and understanding of sensor functionality․ Binderholz provides application guides in PDF format, detailing wood construction techniques․ Furthermore, the CEPAL Ebony & Authentic Risseiche DQ application utilizes the DIETÜR tool for customized door design․

Dental DQ applications, focused on exam preparation, often present as PDF study materials․ Even within research, forms like the CRA joint application (available in Word or PDF) represent a DQ application type․ These varied forms demonstrate the wide-ranging nature of DQ-related requests․

Accessing the DQ Application PDF

Locating the correct DQ application PDF depends entirely on the specific application type․ For Dairy Queen job applications, visiting a local store is a direct route, though online corporate job applications are also available through their careers website․ DQ Advocates Insight Days applications are typically accessed via a dedicated link provided during event announcements or on their recruitment pages․

Technical PDFs, like DrägerSensors DQ data sheets, are generally found on the manufacturer’s official website – Dräger – within their resources or support sections․ Binderholz application guides are similarly available on the Binderholz website․ CEPAL’s DQ application is integrated within the GARANT DIETÜR online tool․

Dental DQ exam materials may be distributed through educational institutions or available for purchase online․ Always verify the source’s legitimacy to ensure you’re accessing a valid and current PDF document․

Downloading and Saving the PDF

Once you’ve located the desired DQ application PDF, the download process is usually straightforward․ Most websites offer a direct download link, often represented by a download icon or a button labeled “Download PDF․” Clicking this initiates the download to your computer’s default download folder․

Upon completion, it’s crucial to save the PDF securely․ Rename the file with a descriptive name, including the application type and date, for easy identification․ Create a dedicated folder on your computer for all application-related documents to maintain organization․

For PDFs requiring a login or registration, follow the on-screen instructions carefully․ Ensure your browser allows pop-ups from the website to prevent download interruptions․ Regularly back up your saved PDFs to a cloud storage service or external drive to prevent data loss․ Always double-check the file integrity after downloading․

Completing the DQ Application Form

DQ application forms require careful attention to detail; ensure all sections are fully completed and supporting documents are properly attached, as specified in the PDF guide․

Required Documents for Application

The necessary documentation for a DQ application varies significantly depending on the specific context․ For the Dental DQ application (2023) and associated exams, applicants must prepare and submit relevant academic transcripts, potentially including proof of completed coursework and examination scores․

DQ Advocates Insight Days applications necessitate a completed application form, often available as a Word or PDF document, detailing personal information, educational background, and a statement of interest․

A Dairy Queen job application, whether obtained online or in-store, typically requires basic employment history, contact details, and availability information․

Technical applications, such as those for DrägerSensors DQ data sheets, may not require a traditional application but instead demand specific project details or usage scenarios․ Binderholz wood construction applications might involve architectural plans and structural calculations․

Always consult the specific DQ application PDF for a comprehensive list of required documents to ensure a complete and successful submission․

Step-by-Step Guide to Filling the Form

Begin by carefully downloading the appropriate DQ application PDF, ensuring it’s the correct version for your intended purpose – dental, advocacy, employment, or technical․ Open the PDF using a reliable PDF reader․

Read the instructions thoroughly before commencing․ Complete all mandatory fields, typically indicated with an asterisk or similar marker․ Use clear, concise language and adhere to any specified formatting guidelines․

For Dairy Queen job applications, accurately detail your work history and availability․ Dental DQ applications require precise academic information․

When submitting electronically, save the completed form with a descriptive filename․ For postal submissions, print clearly and ensure all required attachments are included․ Double-check all entries for accuracy before final submission․

Retain a copy of the completed application and all supporting documents for your records․ Following these steps will streamline the DQ application process․

Common Mistakes to Avoid

A frequent error in DQ application PDFs is incomplete information; ensure all required fields are addressed, particularly regarding work history or academic credentials for dental applications․ Illegible handwriting on paper forms is another common issue – print clearly!

Incorrect file formats or corrupted PDFs during electronic submissions can cause delays․ Always save as specified and test the file before sending․ Failing to attach necessary supporting documents, like transcripts or certifications, is a significant oversight․

Misrepresenting information or providing inaccurate details can disqualify your application․ Carefully review all entries for accuracy․ Ignoring specific formatting requests, such as date formats or character limits, can also lead to rejection․

Finally, submitting the wrong application PDF – for example, a job application for an advocacy program – is a preventable mistake․ Double-check before submitting!

Specific DQ Application Contexts

DQ applications vary widely, from dental exam PDFs requiring MCQs to advocate insight days forms and standard Dairy Queen job requests, each with unique requirements․

Dental DQ Application (2023) & Exam Preparation

The Dental DQ application, specifically for 2023, centers around a rigorous examination process․ Prospective applicants must prepare for a challenging MCQ-based assessment, often distributed in PDF format․ Successful completion hinges on thorough preparation and understanding of relevant dental concepts․

The application itself necessitates the careful attachment of all required documentation․ Missing or improperly formatted documents can lead to disqualification․ The PDF application form serves as the primary means of submitting your credentials and exam responses․

Furthermore, understanding the rules governing graft allocation and HLA DQ incompatibility – as detailed in related documentation – may be crucial depending on the specific dental program․ These documents, often exceeding 57 pages, provide essential context for applicants․ Diligent study and meticulous attention to detail are paramount for success in the Dental DQ application process․

DQ Advocates Insight Days Application

DQ Advocates Insight Days offer a valuable opportunity for aspiring professionals․ The application process requires completion of a specific form, readily available as a PDF document, to express your interest and suitability for the program․

To facilitate a comprehensive review of your request, DQ necessitates a fully completed application form․ This form gathers essential information about your background, motivations, and career aspirations․ Returning the completed form is a critical step in the selection process․

The application is designed to help DQ assess your potential contribution to their team․ Thoughtful and detailed responses are highly encouraged․ The PDF format ensures consistent presentation and ease of review by the selection committee․ Demonstrating a genuine interest in DQ’s advocacy work will significantly strengthen your application․ Prompt submission is also advised to meet any stated deadlines․

Dairy Queen (DQ) Job Application Process

Embarking on a career with Dairy Queen (DQ) is accessible through various avenues․ While online corporate job applications are available, many positions are filled through store-level applications․ Interested candidates can directly request a Dairy Queen application form at their local store;

Although a downloadable PDF version of the standard DQ job application isn’t universally available online, obtaining a physical copy from a store remains the most common method․ This traditional approach allows for direct interaction with store management and a personalized application experience․

Completing the application thoroughly is crucial․ Be prepared to provide detailed work history, educational background, and availability․ DQ values enthusiastic and dedicated team members; Submitting a well-presented application increases your chances of securing an interview․ Remember to showcase your customer service skills and positive attitude – qualities highly sought after at Dairy Queen!

Technical DQ Applications & Data Sheets

DQ technical PDFs include DrägerSensors DQ data, Binderholz wood construction guides, and CEPAL Ebony/Authentic Risseiche DQ applications via the DIETÜR tool․

DrägerSensors DQ Data Sheets & Usage

DrägerSensors DQ data sheets are crucial supplements to the instructions for use concerning sensing heads and transmitters where these sensors are approved․ These documents, typically around 8 pages and 1MB in size, detail specific usage guidelines and technical specifications․

They provide essential information for ensuring correct implementation and optimal performance of the sensors in various applications․ Understanding the data sheet is paramount for technicians and engineers responsible for installation, maintenance, and troubleshooting․ The sheets outline approved applications, limitations, and potential interferences․

Properly referencing these resources guarantees reliable gas detection and contributes to a safer working environment․ Users should always consult the latest version of the data sheet before working with DrägerSensors DQ to ensure compliance and effective operation․ These resources are vital for maximizing sensor lifespan and accuracy․

Binderholz Wood Construction Application Guides

Binderholz provides comprehensive application guides – approximately 16 pages and 5MB in size – offering advice on all solid wood construction products and their implementation․ These guides are invaluable resources for architects, engineers, and construction professionals seeking to utilize Binderholz materials effectively․

The documentation details construction solutions relating to structural statics, fire resistance, and sound insulation, ensuring projects meet stringent building regulations and performance standards․ They cover a wide range of applications, from residential buildings to large-scale commercial structures․

These guides facilitate informed decision-making throughout the building process, promoting efficient and sustainable construction practices․ Accessing these resources ensures optimal utilization of Binderholz products, maximizing their benefits and contributing to durable, high-quality structures․ Proper application, as detailed in these guides, is key to long-term performance․

CEPAL Ebony & Authentic Risseiche DQ Application (DIETÜR Tool)

CEPAL Ebony and CEPAL Authentic Risseiche DQ applications are seamlessly integrated within the DIETÜR online tool from GARANT․ This innovative platform allows users to design their ideal door with just a few clicks, offering a highly customizable experience․

The DIETÜR tool simplifies the selection and configuration process, enabling users to visualize different options and create bespoke door solutions tailored to their specific needs․ It streamlines the design phase, reducing complexity and ensuring accurate specifications․

By combining CEPAL Ebony and CEPAL Authentic Risseiche DQ within DIETÜR, users benefit from a user-friendly interface and a comprehensive range of design possibilities․ This digital approach enhances efficiency and promotes creative exploration, resulting in doors that perfectly complement any interior style․ The tool ensures a precise and visually appealing outcome․